At YIY, quality is our foundation. Through rigorous quality control and advanced laboratories staffed by certified engineers, we validate performance, safety, and durability for every voltage stabilizer. Our zero-defect philosophy—from components to final product—ensures reliability that exceeds international standards and customer expectations.

ISO 9001:2015 Quality Management System

Incoming Quality Control (IQC)

Only quality components that meet stringent specifications will be produced to establish quality excellence.

100% Inspection

Every piece inspected for critical electrical and mechanical parameters

Testing Requirements

Full electrical testing including performance and safety parameters

Tensile Testing

Mechanical strength testing for critical structural components

Supplier Audits

Regular on-site audits of supplier facilities and quality systems

In-Process Quality Control (IPQC)

Continuous monitoring and verification throughout manufacturing processes ensuring consistent quality output and immediate deviation detection.

PCB Assembly

Transformer Manufacturing

Mechanical Assembly

Documentation

Training

Final Quality Control (FQC)

Servo Stabilizer Testing

- Servo motor performance – Speed, torque, positioning accuracy

- Carbon brush contact – Resistance and wear testing

- Mechanical endurance – Extended cycling reliability

- Noise level testing – Acoustic measurement under all conditions

IGBT Stabilizer Testing

- Switching performance – Speed and efficiency validation

- Harmonic analysis – THD measurement and compliance

- EMI/EMC testing – Electromagnetic compatibility verification

- Thermal performance – Heat dissipation and cycling tests

Three-Phase Testing

- Phase balance – Output balance under unbalanced loads

- Phase sequence – Correct sequence and protection verification

- Neutral current – Measurement under various load conditions

- Phase loss protection – Detection and protection function tests

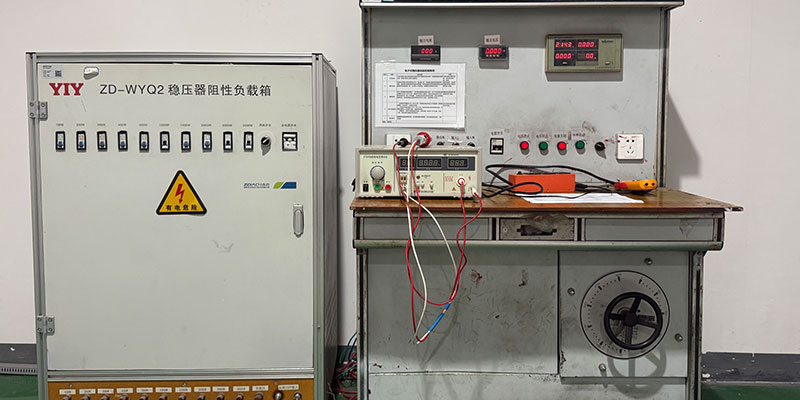

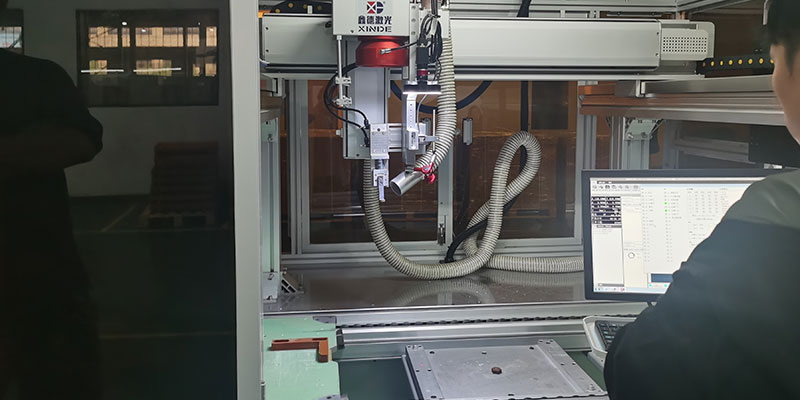

Voltage Stabilizer Testing Laboratory Equipment

YIY’s quality control laboratories feature industry-leading test equipment and measurement systems, providing accurate, reliable, and traceable testing results for all voltage stabilizer products.

Continuous Improvement Programs

YIY’s continuous improvement culture drives systematic enhancement of quality systems, processes, and performance through structured programs that engage all employees in quality improvement activities.