YIY offers a full-range stable voltage solution ranging from 0.5 to 3000 kVA, suitable for residential to industrial applications. With 15 years of R&D experience, over 100 patents, serving more than 130 countries, and typically recovering the cost within 18 months. The customized solution integrates servo, relay and IGBT technologies to ensure continuous protection of equipment and efficient operation.

Comprehensive Voltage Solutions

The Global Voltage Challenge: Power grid instability affects 89% of industrial facilities and 76% of commercial buildings worldwide, causing equipment damage, productivity losses, and safety risks.

- Home appliances suffer 40% shorter lifespan from voltage variations

- Industrial equipment failures cost $50,000-200,000 per hour

- Power quality issues cause 15-30% increase in energy consumption

YIY’s Systematic Approach: YIY voltage stabilizers are based on 15 years of expertise in voltage regulation, 50+ specialized engineers, and 100+ proprietary patent technologies. We transform unstable grid power into precise-controlled electricity that protects equipment, reduces costs, and ensures operational continuity.

Home Voltage Stabilizer Solutions

PRO Servo Voltage Stabilizer

AVR Single-Phase Relay Voltage Stabilizer

Recommended Voltage Stabilizer for Industrial Equipment

SVC-3 (TNS) Three-Phase Servo Motor Type Voltage Stabilizer

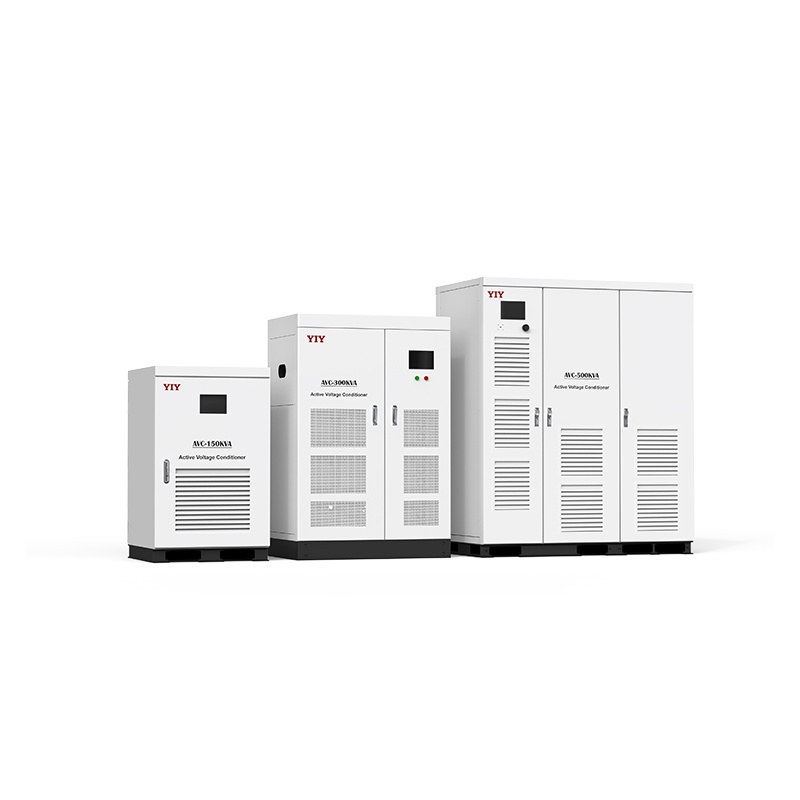

AVC Active Voltage Conditioner

SBW Three-Phase Servo Voltage Stabilizer

Recommended Voltage Stabilizer Specialized Applications

PWR-3 Three-Phase Servo Voltage Stabilizer

OEM Custom Voltage Stabilizer Solutions

Leverage our 50+ R&D engineers and 100+ patents for custom voltage stabilization solutions. From prototype to mass production, comprehensive OEM services backed by 16 years of engineering excellence.

Custom capacity (0.5KVA-5000KVA)

Regional voltage standards

Control interfaces

Environmental specifications

Certification compliance

Success Stories – Proven Voltage Stabilization Solutions

Real-world results from our global installations demonstrate the measurable impact of YIY voltage stabilizers across diverse industries and applications.

Regional Hospital Power Infrastructure

- Challenge:

200-bed hospital experiencing voltage fluctuations affecting critical medical equipment. - Solution:

Comprehensive CVCF and AVC systems protecting MRI, CT, and ICU equipment. - Results:

99.9% uptime improvement, zero voltage-related equipment failures, $500K+ equipment protection value.

Automotive Manufacturing Plant

- Challenge:

CNC machining center productivity loss due to voltage variations. - Solution:

Integrated PRO-3 series stabilizers for 50+ CNC machines. - Results:

25% reduction in scrap rate, 15% increase in production efficiency, 18-month ROI.

Data Center Expansion Project

- Challenge:

New data center requiring precision voltage regulation for 2MW IT load. - Solution:

Parallel AVC systems with N+1 redundancy and SCADA integration. - Results:

99.99% availability achieved, seamless integration with existing UPS systems.

Frequently Asked Question

Our solution selection depends on your specific requirements including load type, capacity, voltage levels, and environmental conditions. Use our online Solution Finder tool or contact our engineers for personalized recommendations.

Yes, we specialize in custom-engineered solutions for unique requirements. Our engineering team can design and manufacture bespoke systems for challenging applications with special voltage, environmental, or performance requirements.

We provide complete support from initial consultation through installation and commissioning. This includes site surveys, design services, project management, installation supervision, and operator training.

All solutions undergo rigorous testing including factory acceptance tests, performance verification, and quality assurance checks. We also provide comprehensive warranties and ongoing maintenance support.

Yes, our solutions are designed for seamless integration with existing electrical infrastructure. We provide detailed integration planning and coordinate with your existing contractors and systems.

Project timelines vary based on complexity. Standard solutions: 4-8 weeks. Custom solutions: 8-16 weeks. Emergency projects can be expedited with dedicated resources and priority manufacturing.

Yes, we have installation and support capabilities in 130+ countries through our global partner network. Local support ensures rapid response times and regional expertise.

We design solutions with future expansion in mind. Our modular designs allow for capacity increases, and we provide upgrade paths as technology advances or requirements change.

Comprehensive training programs include system operation, maintenance procedures, troubleshooting, and safety protocols. Training can be provided on-site or at our facilities.

We work with customers to establish success metrics including uptime improvement, energy savings, equipment protection value, and productivity gains. Regular performance reviews ensure ongoing optimization.